|

Home

Moonshine Stills

Catalog & Shopping Cart

Contact Us

Privacy Policy

Valves

Stills

Gaskets

Distilling Books

Parrot's Beaks

Pumps

Thermometers

Water Storage Tanks

Spirit Storage Tanks

Tri-Clamp Fittings & Tubing

Still & Distilling

Controllers

Used Distilling Equipment

Bottling & Filtering

Equipment

Mash Tuns

Fermenters

Agitators

Cooling Coils

Complete Distilling Systems

Low Pressure Steam Boilers

Still Columns

Grain Mills

100 Gallon Mash Tun

Stripping Still

200 Gallon Mash Tun Stripping

Still

300 Gallon Mash Tun Stripping

Still

400 Gallon Mash Tun

Stripping Still

500 Gallon Mash

Tun Stripping Still

600 Gallon Mash Tun

Stripping Still

800 Gallon Mash Tun

Stripping Still

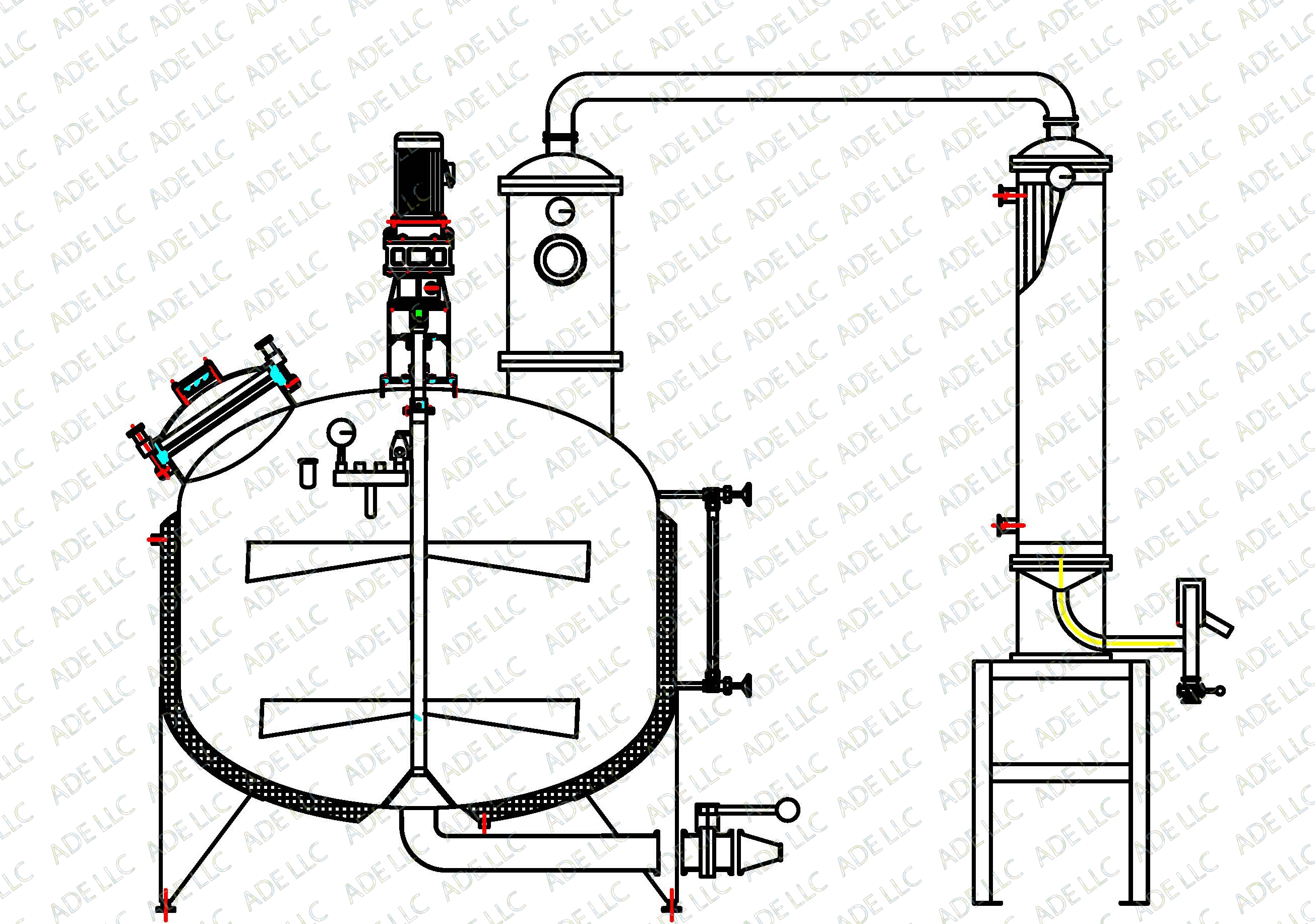

The picture above is of one of our Pro Series Combination Mash Tun Stripping Stills. If you would like to visit the distillery to see this still in

operation and hear what the owner has to say about this still just email us

at

paul@distillery-equipment.com

and we will send you the contact information.

|

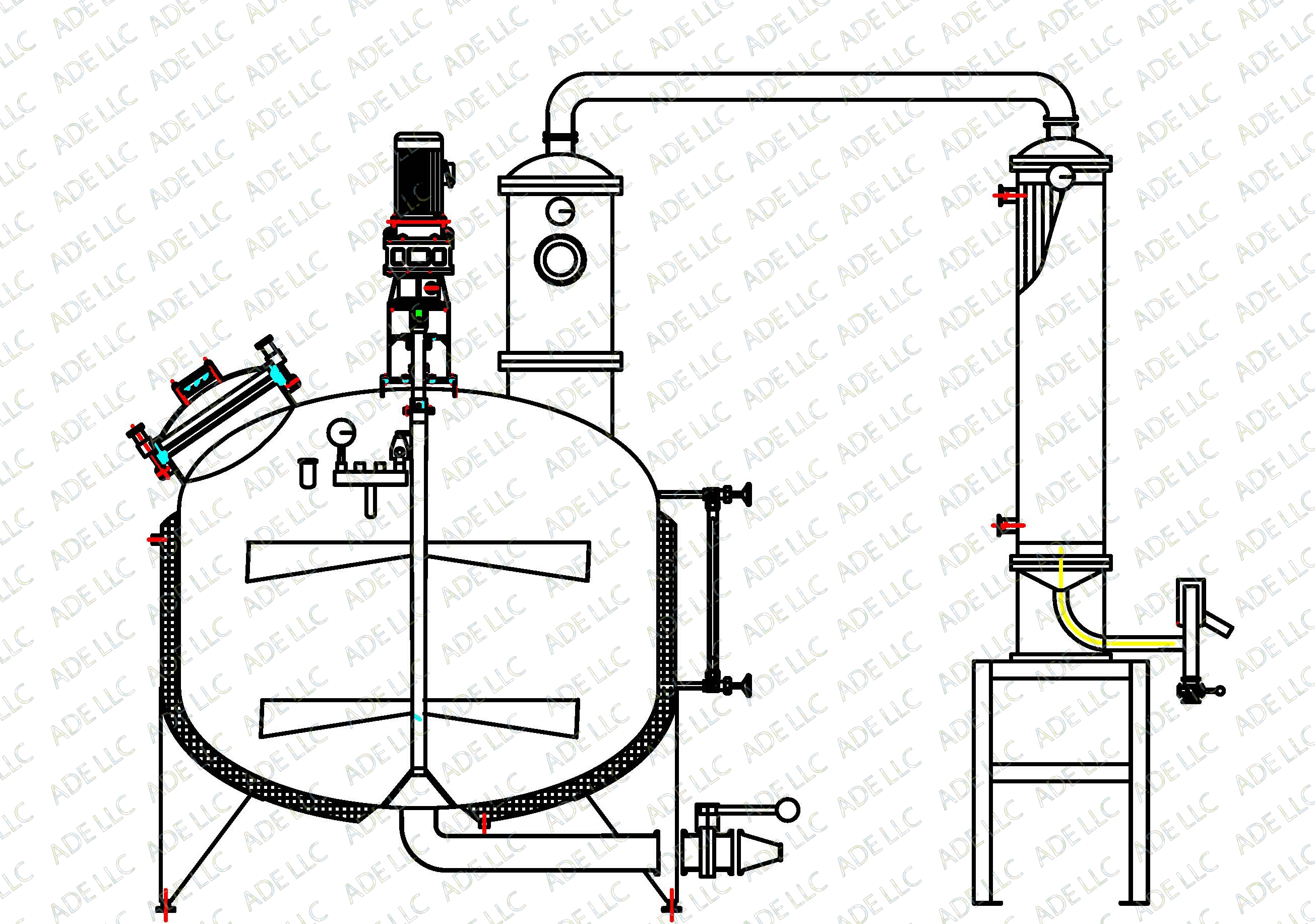

The drawing below shows our newest design.

This new design improves efficiency and decreases mash cooking time.

Prices are the same for the new off center column design and the old

centered column design. The new design has better agitation, while

maintaining the same operating characteristics, as the old design for the stripping

run.

To See Our Catalog with all of our different products

CLICK HERE

|

|

The Design Drawing to the left is of one of our Steam Injected Mash

Tun/Stripping Stills. This unit serves as both a Mash Cooker and

Stripping Still. The HLT supplies hot water for mashing, CIP and any

other process were hot water is needed. The HLT also supplies steam

for cooking the mash and for the Stripping Run as well. If your grain

bill primarily consists of corn than this is the set up for you. This system

has several advantages over direct fire systems.

-

The HLT only costs about 25% of the cost of a low pressure Steam Boiler

which will save you $15,000.00 or more, and even though it is always

better to have a low pressure steam boiler, our steam injected systems gives

you most of the same advantages.

-

This Mash Tun/Stripping Still has a Cooling Jacket for cooling your mash

from 212° F down to 155°F, so that you can throw the Barley Malt, and then

once the Scarification process is complete the Agitator and Cooling Jacket

are used to cool the mash down to 70°F. When purchasing distilling

equipment many people overlook cooling for their mash tun. Having no

way to cool your mash quickly during the cooking and scarification process

is a giant mistake that leads to an inferior product and extends the mashing

time by many hours. Our Steam Jacketed Mash Tuns have cooling jackets as well.

-

With Steam Injection you can leave the grain without having to worry about

scorching the mash during the cooking process.

-

The steam injected stripping run is also done on the grain. The

steam injected stripping run strips every drop of alcohol out of the mash.

There is no residual alcohol left in the mash. Stripping on the

grain, rather than trying to separate the liquids from the solids saves you

thousands of dollars over a span of a few months distilling.

-

The steam injected stripping run separates out the liquids from the

solids which saves you a great deal of time and labor.

-

Since the low wines are liquids with no solids you can run them in a

Direct Fire Spirit Still, which costs thousands less than a jacketed still.

Our steam injection boiler fired systems do have disadvantages compared

to low pressure steam boilers fired systems.

-

Steam injection is noisy because the vessel being injected with

steam makes a banging noise due to the pressure wave created by the hot

steam entering the cold mash. As the temperature of the mash

increases the thumping will decrease in intensity until it finally stops

when the pressure becomes equal.

-

Our steam injection boilers are only about 75% efficient, were as the

Rite Low Pressure Steam Boilers that we sell are around 85% efficient. So

over the long term, low pressure steam boilers are more cost effective.

-

The largest steam injection HLT that we build has a 200 gallon

capacity and produces 320Kbtu The largest still or mash tun that can

be fired by it is 300 gallons.

-

Though we have Steam Injection HLT's that are operating in

distilleries all over the US, a low pressure steam boiler is easier to get

past the inspectors in most instances. However, all of our customers

who purchased our Steam injection HLT's got those units through the

inspection process.

Testing Stills

Complete Testing Still

|